Camera gully – Camera gullies, often unseen yet vital components of urban and industrial infrastructure, play a crucial role in various applications. This guide delves into the world of camera gullies, exploring their design, function, installation, and maintenance. We’ll uncover the different types, materials, and applications of these essential systems, offering a comprehensive understanding of their importance in modern infrastructure.

From their use in drainage systems to their role in security and environmental monitoring, camera gullies are more than just holes in the ground. They represent a sophisticated blend of engineering, technology, and practicality, designed to enhance safety and efficiency in diverse settings. This exploration will cover everything from the basics of their definition to the intricacies of their construction and maintenance.

Camera gully’s hidden surveillance is a fascinating topic; think about how meticulously the games were monitored in Squid Game. The level of observation is similar to the intense scrutiny Guard 44 faced in the deadly competition, as shown in this detailed analysis: guard 44 squid game. Understanding this level of observation helps us appreciate the potential for similar, unseen monitoring in a place like camera gully.

Understanding Camera Gullies

Camera gullies are specialized infrastructure components designed to facilitate visual inspection and monitoring of underground systems. This article provides a comprehensive overview of camera gullies, covering their definition, types, applications, construction, maintenance, and safety considerations.

Defining “Camera Gully”

A camera gully is essentially an access point, typically located underground, equipped with a viewing port or camera system to allow for visual inspection of pipes, conduits, or other subterranean infrastructure. The term might also refer to the entire inspection system, including the camera, lighting, and recording equipment. While there isn’t a universally accepted formal definition, the core function remains consistent: providing a means of visual access to underground utilities.

The term’s usage can vary slightly depending on geographical location and industry jargon. Some might use similar terms like “inspection chamber” or “access point” to describe similar structures. However, “camera gully” specifically highlights the integration of visual inspection technology within the access point itself.

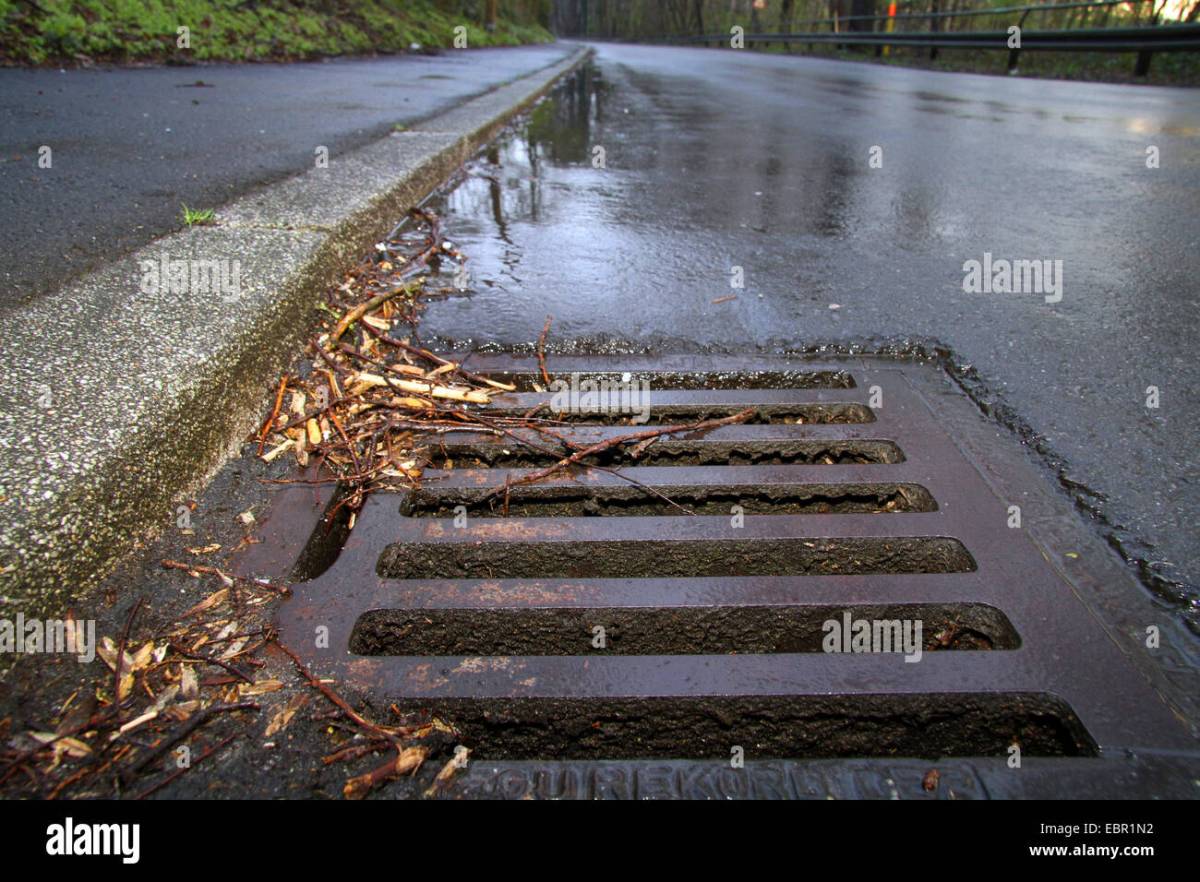

Camera gullies are commonly used in urban areas for managing drainage systems, but their applications extend to rural settings (for agricultural drainage) and industrial sites (for monitoring pipelines).

Types of Camera Gullies

Camera gullies come in various designs, tailored to specific applications and environmental conditions. These variations are primarily determined by their size, material, and integration with other infrastructure components.

| Type | Description | Material | Typical Application |

|---|---|---|---|

| Standard Camera Gully | A basic access point with a viewing port, typically circular or rectangular, designed for easy camera insertion. | Concrete, Plastic, Metal | Municipal drainage systems, small-scale industrial applications |

| High-Capacity Camera Gully | Larger access point designed to accommodate larger diameter pipes and more complex inspection equipment. | Reinforced Concrete, High-Density Polyethylene | Large-diameter pipelines, wastewater treatment plants |

| Combined Camera Gully | Combines the camera access point with other utility access points, such as manholes or access chambers. | Concrete, Fiber Reinforced Polymer | Integrated infrastructure projects, complex utility networks |

| Self-Cleaning Camera Gully | Incorporates a self-cleaning mechanism to reduce maintenance needs. | Stainless Steel, Specialized Plastics | Applications with high sediment loads or frequent debris accumulation |

For example, a standard camera gully in a residential area might be a small, prefabricated concrete unit with a simple access lid and a viewing port suitable for a small inspection camera. In contrast, a large industrial site might utilize a robust, high-capacity camera gully constructed from reinforced concrete or specialized plastics, designed to withstand heavy loads and provide access to large-diameter pipelines.

Camera Gully Applications

Camera gullies play a vital role in various sectors, contributing to efficient infrastructure maintenance and environmental monitoring. Their primary applications include:

- Infrastructure Maintenance: Regular inspections using camera gullies help detect cracks, leaks, blockages, and other issues in drainage systems, pipelines, and conduits, allowing for timely repairs and preventing costly failures.

- Environmental Monitoring: Camera gullies enable the monitoring of water quality, sediment accumulation, and the presence of pollutants in underground systems, aiding in environmental protection and regulatory compliance.

- Security and Surveillance: In certain applications, camera gullies can be integrated into security systems to monitor underground areas for unauthorized access or suspicious activity.

Construction and Maintenance of Camera Gullies

The construction process typically involves excavation, foundation preparation, installation of the gully structure, connection to the drainage system, and sealing. Regular maintenance includes cleaning, inspection, and repairs as needed.

- Excavation and Foundation Preparation

- Installation of the Gully Structure

- Connection to Drainage System

- Sealing and Backfilling

Best practices for maintenance include regular inspections (at least annually), prompt cleaning of accumulated debris, and immediate repair of any damage. Neglecting maintenance can lead to blockages, structural failure, and potential environmental hazards.

Materials Used in Camera Gully Construction

The choice of materials for camera gully construction depends on factors such as the application, environmental conditions, and budget constraints. Common materials include concrete, various plastics (e.g., HDPE, PVC), and metals (e.g., stainless steel).

Concrete offers strength and durability but can be susceptible to cracking. Plastics offer corrosion resistance and lighter weight, while metals provide superior strength but are prone to corrosion in certain environments. The environmental impact varies; concrete has a high carbon footprint, while some plastics can persist in the environment for extended periods.

Camera gully’s a pretty wild place, known for its rugged terrain and unpredictable weather. You wouldn’t believe the drama that unfolded there recently – it reminds me of that time Khabib Nurmagomedov was khabib removed from plane , total chaos! Anyway, back to Camera gully, the best shots are usually taken early morning before the heat haze kicks in.

Visual Representation of Camera Gullies

Imagine a cylindrical camera gully, approximately 1 meter in diameter and 1.5 meters deep, constructed from reinforced concrete. The top features a robust, watertight access lid. Inside, a central viewing port, about 20 centimeters in diameter, allows insertion of a small inspection camera. The gully is seamlessly integrated into a larger drainage network, connecting to a series of underground pipes.

The internal walls are smooth to minimize friction and facilitate easy camera navigation. The system might include internal lighting for improved visibility during inspections.

Safety Considerations with Camera Gullies

Working with camera gullies involves potential hazards, including confined space entry, exposure to hazardous materials, and risks associated with heavy equipment. Safety precautions include proper ventilation, use of personal protective equipment (PPE), and adherence to confined space entry procedures. Regular inspections and preventative maintenance can also minimize risks.

Camera gully’s rugged terrain makes it a tricky location for filming, demanding careful planning and stable equipment. Think about the precision needed – it’s almost like navigating a complex level in a video game, similar to the challenges you’d face in the defender video game , where quick reactions and strategic thinking are key. Back to Camera Gully, though, remember to account for unpredictable weather patterns when scheduling your shoot.

Regulatory guidelines and standards vary depending on the location, but generally involve compliance with occupational safety and health regulations, and potentially specific guidelines for working with underground utilities.

Epilogue

Understanding camera gullies is key to appreciating the complex systems that support our modern world. From their straightforward design to their diverse applications, these unassuming components contribute significantly to safety, efficiency, and environmental monitoring. By recognizing their importance and implementing proper maintenance, we can ensure the continued effectiveness of these vital infrastructure elements. This guide provides a foundation for further exploration and practical application of camera gully knowledge.

General Inquiries: Camera Gully

What are the typical lifespan of camera gullies?

Lifespan varies greatly depending on materials, usage, and maintenance, but can range from 10-30 years.

How often should camera gullies be inspected?

Regular inspections, ideally every 6-12 months, are crucial to identify potential issues early.

What are the costs associated with camera gully installation?

Costs depend heavily on size, materials, location, and complexity of the installation. Get professional quotes for accurate pricing.

Are there specific regulations governing camera gully installation?

Yes, local building codes and regulations often dictate materials, installation methods, and safety standards. Check with your local authorities.